9.0L John Deere Common Rail Injector Troubleshooting: Diagnosing and Solving Common Problems

When it comes to the intricate world of 9.0L John Deere common rail injectors, troubleshooting common issues is an essential skill that every engine enthusiast should master. These powerful components play a crucial role in the efficient operation of your engine, but like any mechanical part, they can encounter problems that disrupt their performance. In this article, we will delve into the realm of diagnosing and solving common problems that plague 9.0L John Deere common rail injectors, equipping you with the knowledge and techniques needed to keep your engine running smoothly.

Imagine your engine as a symphony orchestra, with each component playing a unique role in creating harmonious melodies of power and efficiency. The common rail injector system in a 9.0L John Deere engine is like the conductor, orchestrating the precise delivery of fuel at optimal times to ensure peak performance. However, when this conductor falters, the entire orchestra falls out of tune, leading to a cacophony of issues such as poor engine performance, increased fuel consumption, and ominous black smoke billowing from the exhaust.

So, how can you identify when the conductor is off-key? By paying attention to the telltale signs that your 9.0L John Deere common rail injectors are experiencing trouble. From subtle hesitations in engine power to more obvious symptoms like rough idling and decreased fuel efficiency, these indicators serve as red flags that prompt you to delve deeper into the inner workings of your injector system.

Diagnosing injector problems requires a keen eye and a methodical approach. Pressure testing, visual inspections, and the use of electronic scanning tools are essential techniques that allow you to peer beneath the surface and uncover the root cause of injector malfunctions. Like a skilled detective, you must gather clues from these diagnostic methods to piece together the puzzle of what ails your 9.0L John Deere common rail injectors.

When it comes to troubleshooting common injector issues, a diverse arsenal of techniques is at your disposal. From meticulous cleaning procedures that rid injectors of harmful deposits to precise adjustments of injector timing that restore optimal performance, there are solutions tailored to address a myriad of problems. In cases where components have gone awry, the judicious replacement of faulty parts can breathe new life into your injector system, ensuring that your engine runs like a well-oiled machine once more.

Prevention is often the best cure, and this adage holds true for maintaining the health of your 9.0L John Deere common rail injectors. By implementing proactive measures such as managing fuel quality and conducting regular system checks, you can stave off potential problems before they have a chance to manifest. Just as regular exercise and a balanced diet are essential for a healthy body, preventive maintenance practices are the key to extending the lifespan and efficiency of your injector system.

Understanding Common Rail Injector Systems

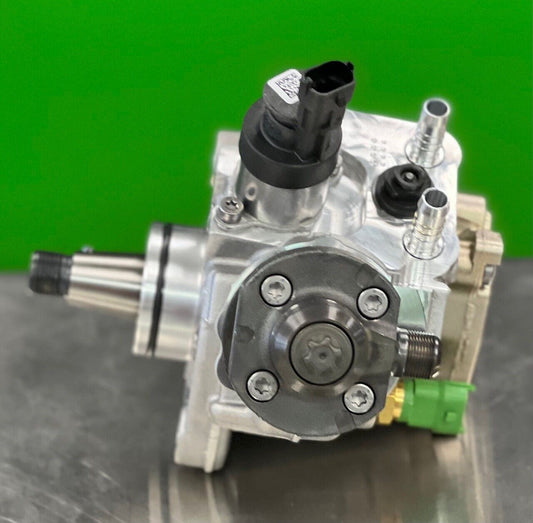

Common rail injector systems play a vital role in the operation of 9.0L John Deere engines, ensuring efficient fuel delivery for optimal performance. These systems are sophisticated and innovative, utilizing advanced technology to precisely control the injection of fuel into the combustion chamber. To comprehend how common rail injectors function, it is essential to delve into the key components that make up these systems.

At the heart of the common rail injector system is the fuel rail, a high-pressure reservoir that stores fuel and distributes it to individual injectors. The injectors, in turn, are responsible for atomizing the fuel into a fine mist and injecting it into the cylinders at the precise moment for combustion. This process is orchestrated by the engine control unit (ECU), which regulates the fuel pressure and injection timing to optimize engine performance.

One of the primary advantages of common rail injector systems is their ability to deliver fuel at extremely high pressures, resulting in better fuel atomization and combustion efficiency. This leads to improved power output, fuel economy, and reduced emissions, making it a preferred choice for modern diesel engines.

Moreover, common rail systems offer flexibility in fuel delivery, allowing for multiple injections per combustion cycle. This capability enhances engine smoothness, reduces noise levels, and contributes to overall driving comfort. By precisely controlling the amount and timing of fuel injected, common rail systems can adapt to varying engine loads and operating conditions with precision.

In essence, understanding the intricacies of common rail injector systems is crucial for diagnosing and resolving issues that may arise during the operation of 9.0L John Deere engines. By grasping the fundamental principles behind these systems, technicians and operators can effectively troubleshoot problems, optimize performance, and ensure the longevity of the engine.

Signs of Injector Problems

When it comes to 9.0L John Deere common rail injectors, recognizing the signs of potential problems is crucial for maintaining optimal engine performance. These signs serve as red flags, indicating that there may be underlying issues with the injectors that require attention. Let's delve into the common signs that point towards injector problems:

- Poor Engine Performance: One of the primary indicators of injector issues is a noticeable decline in engine performance. If your engine is running rough, experiencing misfires, or lacking power, it could be a sign of injector malfunction.

- Increased Fuel Consumption: When injectors are not functioning correctly, they may deliver an improper fuel-air mixture to the engine, leading to increased fuel consumption. If you find yourself refueling more frequently without any apparent reason, it could be due to injector problems.

- Black Smoke Emissions: Another visible sign of injector issues is the emission of black smoke from the exhaust. This occurs when the injectors are not atomizing the fuel properly, resulting in incomplete combustion and the release of excess soot particles.

These signs should not be ignored, as they can escalate into more severe issues if left unaddressed. By promptly identifying and addressing injector problems, you can prevent further damage to your engine and ensure smooth operation. Now that you are aware of the signs to watch out for, you can take proactive steps to diagnose and resolve injector issues efficiently.

Diagnostic Techniques

When it comes to diagnosing issues with 9.0L John Deere common rail injectors, employing effective diagnostic techniques is crucial in identifying the root cause of problems accurately. One of the primary methods used is pressure testing, which involves checking the fuel pressure within the injector system to ensure it meets the required specifications. By conducting pressure tests, technicians can determine if there are any leaks or blockages affecting the injector's performance.

In addition to pressure testing, visual inspections play a vital role in diagnosing injector malfunctions. Technicians carefully examine the injectors for any signs of physical damage, such as cracks or corrosion, that could be contributing to performance issues. Visual inspections can also help identify any loose connections or faulty components that need to be addressed.

Furthermore, electronic scanning tools are commonly used in diagnosing injector problems in modern engines. These tools allow technicians to access the engine control unit (ECU) and retrieve error codes that provide valuable insights into the specific issues affecting the injectors. By analyzing the data from electronic scans, technicians can pinpoint the exact nature of the problem and take appropriate corrective actions.

Moreover, conducting injector balance tests can help determine if all injectors are delivering fuel evenly to the engine cylinders. Any imbalance in fuel delivery can lead to poor engine performance and increased fuel consumption. By performing balance tests, technicians can identify any discrepancies and adjust the injectors accordingly to ensure optimal engine operation.

In some cases, ultrasonic cleaning may be used as a diagnostic technique to remove carbon deposits and other contaminants that can affect injector performance. This method involves using high-frequency sound waves to agitate a cleaning solution, effectively removing buildup from the injectors. Ultrasonic cleaning can help restore injector efficiency and improve overall engine performance.

Common Injector Troubleshooting Methods

When it comes to addressing issues with 9.0L John Deere common rail injectors, there are several common troubleshooting methods that can help resolve problems effectively. These methods are essential in ensuring the optimal performance of the injector system and overall engine efficiency.

One of the primary troubleshooting methods is cleaning procedures. Over time, injectors can accumulate deposits and contaminants that affect their performance. Regular cleaning can help remove these build-ups and restore proper fuel atomization, improving engine performance and fuel efficiency.

Another crucial approach is adjusting injector timing. Incorrect timing can lead to issues such as misfiring, rough idling, and decreased power output. By adjusting the timing settings, technicians can ensure that the injectors deliver fuel at the precise moment for optimal combustion.

In cases where cleaning and timing adjustments are not sufficient, replacing faulty components may be necessary. This can involve replacing worn-out nozzles, seals, or other parts that are causing injector malfunctions. By replacing these components, the injector system can be restored to its proper working condition.

Additionally, performing leak tests can help identify any leaks in the injector system that may be causing fuel pressure issues. By pinpointing and repairing leaks, technicians can prevent fuel wastage and ensure that the injectors operate at the correct pressure levels.

Furthermore, conducting flow tests is crucial in diagnosing injector performance. Flow tests measure the amount of fuel delivered by each injector, helping to identify any disparities in fuel distribution among the injectors. This information is vital for balancing fuel delivery and optimizing engine efficiency.

Moreover, calibrating injectors using specialized equipment can fine-tune their performance to meet the engine's requirements accurately. Calibration ensures that each injector delivers the precise amount of fuel needed for efficient combustion, enhancing overall engine performance.

By employing these common injector troubleshooting methods, technicians can effectively diagnose and resolve issues with 9.0L John Deere common rail injectors, ensuring smooth engine operation and optimal fuel efficiency.

Preventive Maintenance Practices

Preventive maintenance is the key to ensuring the longevity and optimal performance of your 9.0L John Deere common rail injectors. By implementing regular checks and following recommended practices, you can prevent potential issues before they escalate into costly problems. Let's delve into some essential preventive maintenance practices that can help you keep your injectors in top condition.

First and foremost, **fuel quality management** plays a crucial role in preserving the efficiency of your common rail injectors. Contaminated or poor-quality fuel can lead to injector clogging, reduced performance, and overall engine damage. It is imperative to use high-quality fuel from reputable sources and consider using fuel additives to maintain cleanliness and lubrication within the fuel system.

Additionally, **regular system checks** are vital to detect any early signs of injector problems. By conducting routine inspections of the injectors, fuel lines, and associated components, you can identify potential issues before they cause major malfunctions. Visual inspections for leaks, cracks, or unusual wear can provide valuable insights into the overall health of the injector system.

**Scheduled maintenance intervals** should be strictly adhered to as recommended by the manufacturer. Following the prescribed maintenance schedule ensures that the injectors receive timely servicing and component replacements, preventing premature wear and tear. Regular maintenance also allows for adjustments to be made to injector settings, ensuring optimal performance and fuel efficiency.

**Proper storage and handling** of spare injectors and related parts are essential to prevent contamination and damage. Storing injectors in a clean, dry environment and handling them with care during installation and maintenance procedures can help maintain their integrity and functionality. Proper storage practices also involve protecting injectors from dust, debris, and moisture that could compromise their performance.

**Monitoring fuel consumption** and engine performance can provide valuable insights into the health of your injector system. Sudden changes in fuel efficiency, power output, or exhaust emissions can indicate underlying issues with the injectors. Keeping track of these performance metrics allows you to address potential problems promptly and avoid more significant damage to the engine.

**Training and education** for personnel responsible for injector maintenance is essential to ensure proper handling and servicing procedures. Providing training on best practices for injector maintenance, troubleshooting techniques, and safety protocols can help prevent errors and ensure the longevity of the injector system. Well-trained staff can identify issues early on and take the necessary steps to rectify them efficiently.

In conclusion, by incorporating these preventive maintenance practices into your regular maintenance routine, you can significantly extend the lifespan and performance of your 9.0L John Deere common rail injectors. Investing time and effort in proactive maintenance measures can save you from costly repairs and downtime in the long run, ensuring smooth operation and optimal efficiency of your engine.

Frequently Asked Questions

-

What are common signs of injector problems in 9.0L John Deere engines?

Common signs of injector issues include poor engine performance, increased fuel consumption, black smoke emissions, and rough idling. If you notice any of these symptoms, it is advisable to have the injectors inspected and tested for potential malfunctions.

-

How can I diagnose injector problems in a 9.0L John Deere common rail system?

Diagnostic techniques for identifying injector problems may involve pressure testing, visual inspections for leaks or damages, and using electronic scanning tools to analyze injector performance data. These methods help in accurately pinpointing the root cause of injector malfunctions.

-

What preventive maintenance practices can help extend the lifespan of 9.0L John Deere common rail injectors?

Regularly monitoring fuel quality, performing system checks, and following manufacturer-recommended maintenance schedules are essential preventive measures to prolong the lifespan of common rail injectors. Proper maintenance can help prevent potential injector-related issues and ensure optimal engine performance.