LB7 Injector Replacement: Step-by-Step Guide

This article provides a detailed guide on replacing LB7 injectors in diesel engines. From diagnosing injector issues to the step-by-step replacement process, this guide will help you navigate through the replacement procedure effectively.

Diagnosing LB7 Injector Problems

Diagnosing LB7 injector problems is crucial for ensuring the optimal performance of your diesel engine. By recognizing common symptoms of faulty injectors, you can address issues promptly and prevent further damage. One of the key indicators of injector problems is rough idling, where the engine may shake or vibrate excessively. Additionally, if you notice white smoke coming from the exhaust, it could be a sign of injector malfunction. Loss of power or decreased fuel efficiency are also red flags that point towards injector issues.

When faced with these symptoms, it is essential to conduct a thorough diagnosis before proceeding with the replacement process. Utilizing diagnostic tools can help pinpoint the exact injector that is causing the problem. By performing a cylinder balance test, you can identify the specific cylinder experiencing issues, allowing for targeted repairs. Moreover, conducting a visual inspection of the injectors can reveal signs of leaks or clogs that may be affecting performance.

To aid in the diagnosis process, creating a checklist of symptoms and observations can streamline the identification of LB7 injector problems. This checklist can include details such as engine behavior, exhaust smoke color, and any unusual sounds during operation. By systematically analyzing these factors, you can accurately diagnose injector issues and proceed with the necessary repairs.

Tools and Parts Required

Discover the essential tools and replacement parts needed for a successful LB7 injector replacement. When embarking on this task, having the right equipment at hand is crucial for a smooth and efficient process. Here is a comprehensive list of tools and parts required for the LB7 injector replacement:

- Injector Puller: A specialized tool designed to safely extract the injectors from the engine without causing damage.

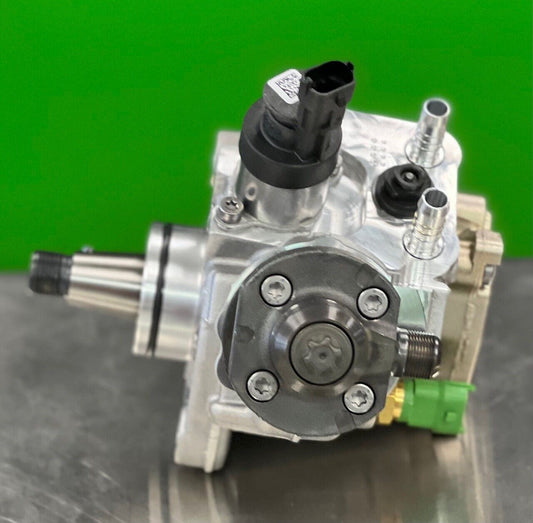

- New LB7 Injectors: Ensure you have high-quality replacement injectors that are compatible with your diesel engine.

- Socket Set: Various socket sizes will be needed to loosen and tighten bolts during the replacement process.

- Torque Wrench: Essential for accurately tightening bolts to the specified torque values to prevent leaks.

- Injector O-Rings: Replacement O-rings to ensure a proper seal between the injectors and the engine.

- Injector Copper Washers: Copper washers that help create a tight seal for the fuel system.

- Engine Cleaner: To clean the area around the injectors before removal to prevent debris from entering the engine.

Having these tools and parts ready before starting the LB7 injector replacement will streamline the process and help you avoid any delays or complications. Proper preparation ensures that you can focus on the task at hand and complete the replacement with confidence.

Preparation Steps

Before diving into the LB7 injector replacement process, it is crucial to prepare adequately to ensure a smooth and successful procedure. Here are the essential steps you need to follow:

- Start by gathering all the necessary tools and parts required for the replacement. This includes injector pullers, new LB7 injectors, torque wrench, and other equipment specified for the task.

- Ensure the engine is cool before starting any work. Working on a cool engine reduces the risk of burns and allows for a more comfortable working environment.

- Disconnect the vehicle's battery to prevent any electrical mishaps during the replacement process. Safety should always be a top priority when working on any automotive project.

- Next, locate the LB7 injectors in the engine compartment. Familiarize yourself with their placement and make sure you have clear access to them for the replacement procedure.

- Prepare a clean and organized workspace to work efficiently. Having a clutter-free environment will make it easier to handle delicate parts and prevent any components from getting misplaced.

By following these preparation steps diligently, you set yourself up for a successful LB7 injector replacement process. Taking the time to prepare adequately will not only streamline the replacement procedure but also ensure the safety of both yourself and your vehicle.

LB7 Injector Replacement Procedure

Replacing LB7 injectors in diesel engines is a meticulous process that requires attention to detail and precision. To start the LB7 injector replacement procedure, gather all the necessary tools and replacement parts as outlined in the previous section. Once you have everything ready, follow these step-by-step instructions to ensure a successful replacement:

- Step 1: Begin by disconnecting the battery to prevent any electrical mishaps during the replacement process. Safety should always be a top priority.

- Step 2: Remove the valve covers carefully to access the LB7 injectors. Take your time to avoid damaging any components.

- Step 3: Use the appropriate tools, such as injector pullers, to remove the old injectors from the engine. Be gentle to avoid causing any harm to the surrounding parts.

- Step 4: Clean the injector ports thoroughly before installing the new injectors. This will help ensure proper seating and functioning of the new components.

- Step 5: Carefully insert the new LB7 injectors into their designated ports, making sure they are securely in place. Avoid forcing them in to prevent damage.

- Step 6: Reattach the valve covers and ensure they are properly sealed to prevent any oil leaks. Double-check all connections and fastenings.

- Step 7: Once the new injectors are installed, reconnect the battery and start the engine to test the functionality of the replacement parts.

Following these steps diligently will help you complete the LB7 injector replacement procedure efficiently and effectively. Remember to pay close attention to detail and take your time to ensure everything is done correctly. If you encounter any issues during the process, don't hesitate to seek professional assistance to avoid further complications.

Testing and Final Checks

After successfully replacing the LB7 injectors in your diesel engine, it is crucial to perform thorough testing and final checks to ensure everything is in proper working order. One of the essential post-replacement procedures is conducting leak tests to verify that the new injectors are properly sealed and functioning without any leaks. This step is vital in preventing potential issues and ensuring the longevity of your engine.

In addition to leak tests, it is recommended to perform engine performance evaluations to assess the overall functionality of the new LB7 injectors. By conducting performance tests, you can ensure that the injectors are delivering the right amount of fuel to the engine for optimal performance. This step is essential in guaranteeing that your engine operates efficiently and effectively after the replacement process.

Furthermore, it is advisable to check for any abnormal sounds or vibrations during the testing phase, as these could indicate potential issues with the newly replaced injectors. Any unusual noises or vibrations should be promptly addressed to prevent further damage to the engine. By paying attention to these details during testing, you can catch any potential problems early on and address them before they escalate.

Once the testing procedures are completed, it is important to perform a final visual inspection of the engine compartment to ensure that everything is properly reassembled and secured. Check all connections, hoses, and components to confirm that they are correctly installed and tightened. This final check is crucial in preventing any potential leaks or malfunctions that could arise from improper assembly.

In conclusion, thorough testing and final checks are essential steps in the LB7 injector replacement process. By following these procedures diligently, you can ensure that the new injectors are functioning correctly and that your engine is operating at its best. Remember, attention to detail during testing can save you from future headaches and ensure the longevity of your diesel engine.

```htmlFrequently Asked Questions

-

What are the common signs of LB7 injector problems?

Common signs of LB7 injector issues include rough idling, white smoke from the exhaust, and a noticeable loss of power in the engine. If you experience any of these symptoms, it is recommended to diagnose the injectors promptly.

-

What tools and parts are essential for LB7 injector replacement?

Essential tools for LB7 injector replacement include injector pullers, socket wrench set, torque wrench, and new injectors. It is crucial to have the necessary replacement parts and equipment to ensure a successful injector replacement process.

-

How can I test the new LB7 injectors after replacement?

After replacing LB7 injectors, conduct post-replacement testing procedures such as leak tests and engine performance evaluations. These tests will help verify the proper functioning of the new injectors and ensure the success of the replacement process.