LB7 Injectors: Common Problems and Solutions

LB7 injectors are essential components in diesel engines, responsible for delivering fuel into the combustion chamber with precision and efficiency. However, like any mechanical part, they are prone to various issues that can affect engine performance. From clogging and leaking to misfiring and decreased fuel economy, LB7 injectors can present a range of common problems that need to be addressed promptly.

When these injectors malfunction, they can disrupt the engine's operation, leading to reduced power, rough idling, and even potential damage if left unresolved. Understanding the signs of injector problems is crucial for vehicle owners to take timely action and prevent further complications.

Diagnosing faulty LB7 injectors requires a systematic approach, utilizing visual inspections, fuel pressure tests, and electronic diagnostic scans. These methods help pinpoint the exact issue and determine the most effective solution to restore the injectors' optimal function.

Repairing LB7 injectors can involve various approaches, such as cleaning to remove deposits, rebuilding to replace worn components, or ultimately replacing the injectors altogether. Each option comes with its costs and benefits, requiring careful consideration based on the extent of the damage and budget constraints.

Preventive maintenance plays a crucial role in ensuring the longevity of LB7 injectors. By following recommended guidelines, such as using high-quality fuel, conducting regular inspections, and replacing injectors as needed, vehicle owners can mitigate common problems and extend the lifespan of their engines.

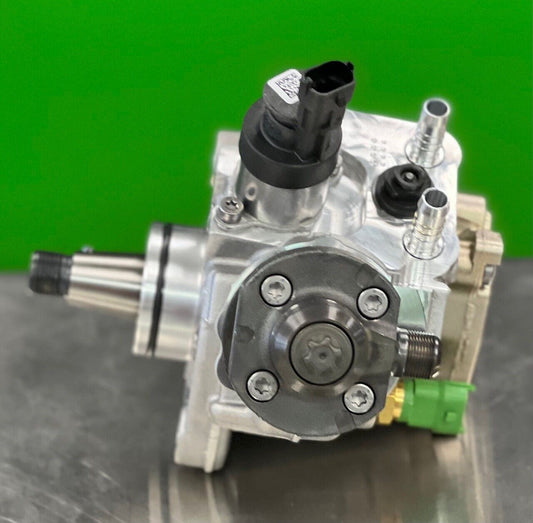

Overview of LB7 Injectors

The LB7 injectors are vital components in diesel engines, responsible for delivering fuel into the combustion chamber with precision and efficiency. These injectors play a crucial role in the engine's performance, ensuring optimal fuel consumption and power output. However, like any mechanical part, LB7 injectors are prone to wear and tear over time, leading to various issues that can impact engine operation.

One of the common signs of injector problems in LB7 engines is a noticeable decrease in performance, including rough idling, reduced power, and increased fuel consumption. Users may also experience issues such as engine misfires, rough starts, and black smoke emissions, indicating potential injector malfunctions. Recognizing these symptoms is essential for diagnosing and addressing injector issues promptly.

To maintain optimal performance and prevent injector problems, regular inspections and maintenance are crucial. Using high-quality fuel, adhering to recommended service intervals, and monitoring engine performance can help identify potential issues early on. Additionally, ensuring proper fuel filtration and injector cleanliness can extend the lifespan of LB7 injectors and improve overall engine efficiency.

Common Problems with LB7 Injectors

When it comes to LB7 injectors, users may encounter a variety of common problems that can significantly impact the performance of their diesel engines. One of the primary issues faced by LB7 injectors is clogging, which can occur due to the accumulation of dirt, debris, or contaminants in the injector nozzles. This can lead to restricted fuel flow and poor engine performance.

Another prevalent problem is leaking injectors, where fuel may leak from the injector nozzles or seals, causing fuel wastage and potential safety hazards. Additionally, misfiring injectors can result in uneven engine operation, leading to rough idling, reduced power, and increased fuel consumption.

Moreover, LB7 injectors may experience poor fuel efficiency, causing the engine to consume more fuel than necessary. This can be attributed to issues such as improper fuel atomization, incorrect fuel delivery, or injector wear and tear. Addressing these common problems is crucial to maintaining the overall health and efficiency of the diesel engine.

To effectively tackle these issues, users need to be vigilant about the signs of injector problems and take proactive measures to diagnose and address them promptly. By understanding the common problems associated with LB7 injectors, individuals can ensure optimal engine performance and longevity.

Diagnostic Methods for LB7 Injectors

When it comes to diagnosing issues with LB7 injectors, precision and accuracy are key. Various methods and tools are utilized to pinpoint the exact problem and ensure effective solutions. One common diagnostic approach is through visual inspections, where experts examine the injectors for any visible signs of damage, clogging, or leakage. This method allows for a quick initial assessment of the injectors' condition.

Additionally, fuel pressure tests play a crucial role in identifying potential problems with LB7 injectors. By measuring the pressure at which fuel is delivered to the injectors, technicians can determine if there are any irregularities that could be causing issues such as misfiring or poor performance. This method provides valuable insights into the functioning of the injectors and helps in diagnosing underlying issues.

Electronic diagnostic scans are another effective tool used to diagnose faulty LB7 injectors. These scans involve connecting specialized equipment to the vehicle's onboard computer system to retrieve error codes and data related to the injectors' performance. By analyzing this information, technicians can identify specific issues affecting the injectors and develop targeted solutions to address them.

In some cases, a combination of these diagnostic methods may be necessary to accurately assess the condition of LB7 injectors. By leveraging the strengths of each approach, technicians can ensure a comprehensive evaluation of the injectors and provide appropriate recommendations for repair or maintenance. Timely and thorough diagnostics are essential in maintaining the optimal performance of LB7 injectors and preventing potential engine problems down the line.

Repairing LB7 Injectors

When it comes to addressing issues with LB7 injectors, there are several repair options available to restore optimal performance to your diesel engine. One common problem that users encounter is clogging, which can lead to poor fuel delivery and engine misfires. In such cases, cleaning the injectors may be a cost-effective solution to remove any built-up deposits and improve fuel atomization.

However, if the injectors are severely clogged or damaged, rebuilding or replacing them may be necessary. Rebuilding the injectors involves disassembling the components, replacing worn parts, and reassembling them to factory specifications. On the other hand, replacing the injectors with new ones ensures reliable performance but may come at a higher cost.

Before deciding on the repair method, it is essential to diagnose the exact issue affecting the injectors. Visual inspections can help identify external damage or leaks, while fuel pressure tests can determine if the injectors are delivering fuel at the correct pressure. Electronic diagnostic scans provide detailed insights into injector performance and can pinpoint any underlying issues that may not be visible during manual inspections.

It is crucial to consider the costs and benefits of each repair approach to make an informed decision. Cleaning the injectors may be a quick fix for minor issues, while rebuilding or replacing them can provide long-term reliability. Regular maintenance and timely repairs can extend the lifespan of LB7 injectors and ensure optimal engine performance.

Preventive Maintenance for LB7 Injectors

When it comes to ensuring the longevity and optimal performance of LB7 injectors, preventive maintenance plays a crucial role. By following a few simple guidelines and best practices, you can significantly reduce the risk of encountering common injector problems. Let's delve into the key preventive maintenance measures that can help you keep your LB7 injectors in top condition.

First and foremost, using quality fuel is essential for the health of your LB7 injectors. Low-quality or contaminated fuel can lead to injector clogging, which in turn affects engine performance. Investing in clean and reputable fuel sources can go a long way in preventing potential issues with your injectors.

Regular inspections are also vital in maintaining LB7 injectors. By visually checking the injectors for any signs of damage, leaks, or buildup, you can catch potential problems early on and address them before they escalate. Additionally, conducting fuel pressure tests at regular intervals can help ensure that the injectors are functioning optimally.

Timely replacements of injector components are crucial preventive maintenance steps. Over time, injector parts can wear out or become less effective, impacting overall engine performance. By replacing worn-out components promptly, you can prevent more significant issues down the line and extend the life of your LB7 injectors.

Furthermore, adhering to manufacturer-recommended maintenance schedules is key to keeping LB7 injectors in top shape. Following prescribed maintenance intervals for cleaning, servicing, and inspecting injectors can help you stay ahead of potential problems and maintain peak engine performance.

In conclusion, preventive maintenance for LB7 injectors is a proactive approach to ensuring smooth engine operation and avoiding costly repairs. By incorporating these maintenance practices into your routine, you can enjoy reliable performance from your LB7 injectors for years to come.

Frequently Asked Questions

-

What are the common signs of LB7 injector problems?

The common signs of LB7 injector problems include clogging, leaking, misfiring, and decreased fuel efficiency. These issues can lead to engine performance issues and should be addressed promptly.

-

How can I diagnose faulty LB7 injectors?

Diagnosing faulty LB7 injectors can be done through visual inspections, fuel pressure tests, and electronic diagnostic scans. These methods help pinpoint the exact issue with the injectors for effective repair.

-

What are the repair options for LB7 injectors?

Repair options for LB7 injectors include cleaning, rebuilding, or replacing the injectors. Each approach has its own costs and benefits, so it's essential to choose the most suitable option based on the injector's condition.

-

How can I prevent common problems with LB7 injectors?

Preventive maintenance is key to avoiding common problems with LB7 injectors. This includes using quality fuel, conducting regular inspections, and replacing injectors in a timely manner to ensure the longevity of the engine.