LB7 Injectors: What You Need to Know

When it comes to LB7 injectors, there is a world of information and considerations that every diesel engine enthusiast should be aware of. These essential components play a crucial role in the fuel delivery system, ensuring that your engine runs smoothly and efficiently. But what exactly do you need to know about LB7 injectors? Let's dive into the details to uncover their function, common issues, maintenance tips, replacement process, cost factors, and where to find reputable sources for purchasing.

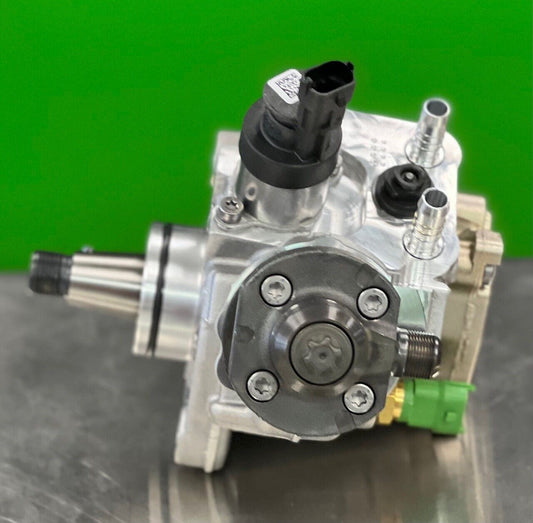

Function of LB7 Injectors

LB7 injectors play a crucial role in the fuel delivery system of diesel engines, acting as the gateway for injecting fuel into the combustion chamber. Think of them as tiny, precision-controlled valves that release the right amount of fuel at the right time to ensure smooth engine operation. Without properly functioning injectors, the engine's performance can suffer, leading to issues like rough idling, decreased power output, and even engine stalling.

These injectors are designed to atomize fuel into a fine mist, allowing for efficient combustion when mixed with air in the engine. By delivering fuel in a precise manner, LB7 injectors help maximize fuel efficiency and power output, contributing to the overall performance of the vehicle. In essence, they are the silent heroes that keep the engine running smoothly and efficiently.

When LB7 injectors are working optimally, they ensure that the engine runs at its best, providing the power needed for acceleration, towing, and daily driving. Their function is essential for maintaining the balance between fuel delivery and combustion, ultimately impacting the vehicle's overall performance and longevity.

Common Issues with LB7 Injectors

When it comes to LB7 injectors, there are several common issues that diesel engine owners may encounter. These issues can significantly impact the performance and efficiency of the vehicle. One of the primary problems associated with LB7 injectors is clogging, which can occur due to the accumulation of dirt, debris, or contaminants in the fuel system. This can lead to fuel flow restrictions and hinder the proper functioning of the injectors.

Leaks are another prevalent issue with LB7 injectors. These leaks can develop due to wear and tear over time or as a result of improper installation. When injectors leak, it can lead to fuel wastage, engine misfires, and even potential safety hazards. It is crucial to address leaks promptly to prevent further damage to the engine and ensure optimal performance.

Misfires are also a common problem associated with LB7 injectors. A misfire occurs when the injector fails to deliver the right amount of fuel to the combustion chamber, resulting in an incomplete combustion process. This can lead to rough idling, reduced power output, and increased emissions. Diagnosing and resolving misfires promptly is essential to avoid more severe engine issues.

Furthermore, reduced fuel efficiency is a notable issue that diesel engine owners may face with LB7 injectors. When injectors are not functioning correctly, they may deliver an insufficient amount of fuel to the engine, leading to decreased fuel efficiency and increased fuel consumption. This can result in higher operating costs and a less environmentally friendly vehicle. Regular maintenance and timely repairs can help address these efficiency issues.

Maintenance Tips for LB7 Injectors

When it comes to maintaining LB7 injectors, there are several crucial tips to keep in mind to ensure they function optimally. One key aspect to consider is the quality of fuel being used. Always opt for high-quality diesel to prevent any potential issues that may arise from impurities or contaminants in lower-grade fuel. Regular inspections are also essential in detecting any early signs of wear or damage to the injectors.

Cleaning procedures play a vital role in the maintenance of LB7 injectors. Periodically cleaning the injectors can help prevent clogging and ensure a smooth fuel delivery process. Additionally, investing in professional cleaning services can further enhance the performance and longevity of the injectors.

Implementing preventative measures is another effective way to prolong the lifespan of LB7 injectors. This includes using fuel additives that can help clean and lubricate the injectors, reducing the risk of buildup and improving overall efficiency. Regularly checking for leaks and addressing them promptly can also prevent more significant issues from arising.

Moreover, staying proactive with maintenance schedules and adhering to manufacturer recommendations can significantly impact the durability and performance of LB7 injectors. By following these maintenance tips diligently, you can ensure that your LB7 injectors operate at their best and avoid costly repairs or replacements in the future.

Replacement Process for LB7 Injectors

When it comes to replacing LB7 injectors, it's crucial to follow a systematic process to ensure optimal performance and efficiency. The replacement process involves several key steps that need to be executed with precision and care. Here's a detailed guide on how to go about replacing LB7 injectors:

- Diagnosing the Need for Replacement: The first step is to identify any signs or symptoms indicating that the LB7 injectors need to be replaced. This may include issues like rough idling, engine misfires, decreased fuel efficiency, or visible leaks.

- Selecting the Right Injectors: Once the need for replacement is confirmed, it's essential to choose the correct LB7 injectors for your specific diesel engine model. Ensuring compatibility is crucial for seamless installation and optimal performance.

- Hiring a Professional Mechanic: While some experienced individuals may opt for a DIY approach, it's highly recommended to seek the expertise of a qualified mechanic for injector replacement. Professional installation can prevent costly mistakes and ensure the job is done right.

- Ensuring Proper Installation: Proper installation of LB7 injectors is critical for the overall function of the diesel engine. This includes securely fastening the injectors, connecting all necessary components, and testing the system for leaks or malfunctions.

By following these steps diligently, you can effectively replace LB7 injectors and restore the performance of your diesel engine. Remember, precision and attention to detail are key when dealing with intricate components like injectors. Don't hesitate to seek professional help if needed to guarantee a successful replacement process.

Cost Factors and Considerations

When it comes to dealing with LB7 injectors, understanding the cost factors and considerations is crucial for making informed decisions. The price of injectors themselves can vary depending on the brand, quality, and whether they are new or remanufactured. Additionally, labor costs for injector replacement or repair should be factored in, as the expertise of a professional mechanic is often necessary for a successful installation.

Moreover, it's essential to consider any additional parts that may be required during the injector replacement process. This could include gaskets, seals, or other components that need to be replaced along with the injectors to ensure optimal performance. These additional parts can contribute to the overall cost of the repair or replacement job.

Before committing to any expenses related to LB7 injectors, it's wise to assess the overall investment required. This includes not only the immediate costs of purchasing injectors and paying for labor but also the long-term benefits of having properly functioning injectors in your diesel engine. Investing in high-quality injectors and professional installation can lead to improved performance and fuel efficiency, potentially saving you money in the long run.

Frequently Asked Questions

-

Q: What are the signs that my LB7 injectors may need replacement?

A: Some common signs that indicate potential issues with LB7 injectors include rough idling, engine misfires, decreased fuel efficiency, and black smoke from the exhaust. If you notice any of these symptoms, it may be time to have your injectors inspected.

-

Q: Can I clean my LB7 injectors instead of replacing them?

A: While cleaning injectors can help improve performance, it may not always resolve underlying issues. If your LB7 injectors are severely clogged or damaged, cleaning may not be sufficient, and replacement could be necessary for optimal engine function.

-

Q: How long do LB7 injectors typically last?

A: The lifespan of LB7 injectors can vary depending on usage, maintenance, and driving conditions. On average, LB7 injectors can last between 100,000 to 200,000 miles. Regular maintenance and using high-quality fuel can help prolong their lifespan.

-

Q: Are there aftermarket LB7 injectors available, and are they reliable?

A: Yes, there are aftermarket LB7 injectors on the market. While some aftermarket options can be reliable and cost-effective, it is essential to research and choose reputable brands to ensure compatibility and performance. Consulting with a professional mechanic can also help in selecting the right injectors for your vehicle.