The Science Behind Fuel Injector Functionality

Have you ever considered the intricate dance of precision and power that occurs within your vehicle's engine every time you start it up? Enter the unsung hero of this performance - the fuel injector. Let's dive into the fascinating world of fuel injector functionality and uncover the science behind its crucial role in the heart of your vehicle.

What is a Fuel Injector?

A fuel injector is a crucial component in a vehicle's engine that plays a vital role in the combustion process. It is essentially a small nozzle that delivers the right amount of fuel into the combustion chamber at the precise moment it is needed. Think of it as a precision instrument that ensures the engine receives the correct fuel-air mixture for optimal performance. Without fuel injectors, the engine would not be able to function efficiently, leading to poor fuel economy, reduced power output, and increased emissions.

How Fuel Injectors Work

The operation of fuel injectors in a vehicle's engine is akin to a precisely choreographed dance, where each movement must be perfectly timed and executed for optimal performance. Fuel injectors are like the gatekeepers of your engine, controlling the flow of fuel into the combustion chamber with remarkable precision. These small but mighty components play a crucial role in the internal combustion process, ensuring that the engine receives the right amount of fuel at the right time.

When you turn the key in the ignition, a series of events are set into motion that culminate in the powerful explosion needed to propel your vehicle forward. Fuel injectors are responsible for delivering the fuel into the combustion chamber in a fine mist, where it mixes with air and is ignited by the spark plug. This controlled explosion generates the power needed to drive the pistons and ultimately, your vehicle.

Inside a fuel injector, a solenoid valve is actuated by the engine control unit, opening and closing with split-second precision to regulate the flow of fuel. The fuel is pressurized by the fuel pump before being sprayed through a tiny nozzle at high velocity into the intake manifold. This atomized fuel-air mixture is then drawn into the combustion chamber, where it is ignited to produce the energy that drives the engine.

Imagine a symphony orchestra, with each instrument playing its part to create a harmonious melody. In the same way, fuel injectors work in perfect harmony with the engine's other components to ensure smooth and efficient operation. By delivering fuel in a controlled manner, fuel injectors help optimize fuel efficiency, engine performance, and emissions levels.

Modern fuel injection systems have evolved to incorporate advanced technologies such as direct injection and multi-point injection, further enhancing engine efficiency and power output. These systems are designed to deliver fuel more precisely, resulting in better combustion and improved overall performance.

In essence, fuel injectors are the unsung heroes of your vehicle's engine, working tirelessly behind the scenes to keep everything running smoothly. By understanding how fuel injectors work and their impact on engine performance, you can better appreciate the intricate engineering that goes into powering your daily commute or thrilling road trip.

Fuel Injector Components

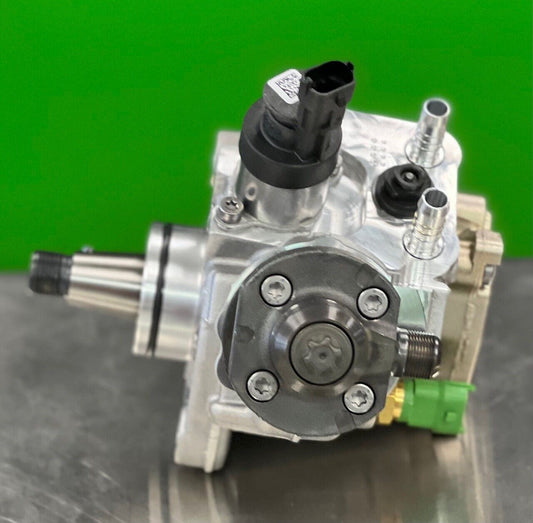

When it comes to understanding the intricate workings of a fuel injector, it is crucial to delve into the components that make up this vital automotive part. Fuel injector components play a pivotal role in the efficient delivery of fuel to the engine, ensuring optimal combustion and performance. Let's explore the key elements that make up a fuel injector and their functions within the fuel delivery system.

One of the essential components of a fuel injector is the nozzle, responsible for precisely spraying the fuel into the combustion chamber in a fine mist. This atomization process is crucial for ensuring proper fuel-air mixture and efficient combustion within the engine. The nozzle's design and construction significantly impact fuel efficiency and engine power.

Another critical component is the fuel filter, which ensures that the fuel entering the injector is free from any contaminants or debris that could clog the system. A clean fuel filter is essential for maintaining the optimal performance of the fuel injector and preventing potential damage to the engine.

The fuel rail acts as a conduit for delivering pressurized fuel to the injectors from the fuel pump. This component plays a vital role in regulating the fuel pressure within the system, ensuring consistent and reliable fuel delivery to the engine under various operating conditions.

Within the fuel injector, the solenoid serves as the electromagnetic actuator that controls the opening and closing of the injector's valve. This precise control allows for the accurate metering of fuel into the combustion chamber, optimizing fuel consumption and engine performance.

Additionally, the injector coil is responsible for generating the magnetic field that activates the solenoid and controls the injector's operation. This component plays a crucial role in the overall functionality and responsiveness of the fuel injector, ensuring timely and accurate fuel delivery to the engine.

In modern fuel injection systems, advanced components such as electronic control units (ECUs) and fuel pressure regulators further enhance the efficiency and performance of fuel injectors. These components work in tandem to monitor and adjust fuel delivery based on various engine parameters, ensuring optimal combustion and power output.

Understanding the intricate interplay of these fuel injector components is essential for maintaining the health and performance of your vehicle's engine. Regular maintenance and inspection of these components can help prevent potential issues and ensure smooth operation on the road.

Fuel Injection Systems Types

When it comes to fuel injection systems, there is a diverse range of types that cater to different engine configurations and performance needs. These systems play a crucial role in delivering the right amount of fuel to the engine for optimal combustion. Let's delve into the various fuel injection systems types that are commonly found in modern vehicles.

1. Port Fuel Injection (PFI): This type of fuel injection system injects fuel into the intake ports just before the intake valve. PFI systems are known for their reliability and cost-effectiveness, making them a popular choice in many vehicles.

2. Direct Fuel Injection (DFI): In DFI systems, fuel is injected directly into the combustion chamber. This allows for more precise control over the fuel delivery, resulting in improved fuel efficiency and engine performance.

3. Sequential Fuel Injection: Sequential fuel injection systems deliver fuel to each cylinder in a specific sequence based on the engine's firing order. This precise timing ensures optimal fuel distribution and combustion efficiency.

4. Throttle Body Injection (TBI): TBI systems inject fuel into the throttle body, which then distributes it to the individual cylinders. While not as efficient as other types, TBI systems are known for their simplicity and ease of maintenance.

5. Common Rail Fuel Injection: Common rail systems use a high-pressure fuel rail to deliver fuel to the injectors. This technology allows for finer control over the fuel injection process, resulting in improved engine performance and reduced emissions.

6. Multi-Point Fuel Injection (MPFI): MPFI systems have individual injectors for each cylinder, allowing for precise fuel delivery to optimize combustion. This type of system is commonly found in modern vehicles for its efficiency and performance benefits.

Each fuel injection system type has its own set of advantages and disadvantages, and the choice of system depends on factors such as engine design, performance requirements, and fuel efficiency goals. Understanding the differences between these systems is essential for both vehicle owners and mechanics to ensure proper maintenance and troubleshooting when issues arise.

Common Fuel Injector Issues

Common Fuel Injector Issues can be a real headache for vehicle owners, causing unexpected breakdowns and performance issues. One of the most common problems is clogging, where dirt, debris, or fuel additives block the injector nozzles, disrupting the fuel flow. This can lead to engine misfires, rough idling, and decreased fuel efficiency. Another issue is leakage, where the injector seals or O-rings fail, causing fuel to leak into the engine or onto the ground. This not only wastes fuel but can also be a fire hazard.

Additionally, fuel injectors can suffer from electrical problems, such as wiring issues or faulty connectors, leading to irregular fuel delivery to the engine. This can result in poor acceleration, stalling, or even engine failure. Over time, injectors can also wear out due to constant use, leading to decreased performance and fuel economy. It's essential to address these issues promptly to avoid more significant problems down the road.

When faced with fuel injector issues, it's crucial to diagnose the root cause accurately. Using specialized diagnostic tools, mechanics can pinpoint the exact problem and determine the best course of action. Cleaning the injectors using specialized cleaning solutions can often resolve clogging issues, restoring proper fuel flow and engine performance.

If leakage is the problem, replacing the seals or O-rings is necessary to prevent fuel wastage and potential safety hazards. In cases of electrical issues, repairing or replacing the wiring and connectors can restore proper injector function. In severe cases of injector wear, replacement may be the only solution to ensure optimal engine performance.

Regular maintenance and inspection of fuel injectors are key to preventing these common issues. Using high-quality fuel, keeping the fuel system clean, and following the manufacturer's recommended maintenance schedule can help prolong the life of your injectors and ensure smooth engine operation. By staying proactive and addressing any issues promptly, you can avoid costly repairs and keep your vehicle running smoothly for years to come.

Frequently Asked Questions

-

What are the signs of a failing fuel injector?

Common signs of a failing fuel injector include rough idling, engine misfires, decreased fuel efficiency, and a noticeable decrease in engine performance. If you experience any of these symptoms, it is recommended to have your fuel injectors inspected and serviced by a professional mechanic.

-

How often should fuel injectors be cleaned?

The frequency of fuel injector cleaning depends on various factors such as the age of the vehicle, driving conditions, and the type of fuel used. As a general guideline, it is recommended to have your fuel injectors cleaned every 30,000 miles or as advised by your vehicle's manufacturer.

-

Can I replace a single fuel injector or do I need to replace all of them?

In most cases, it is not necessary to replace all fuel injectors if only one is faulty. However, it is important to ensure that the new injector matches the specifications of the existing ones to maintain proper engine performance and fuel efficiency.

-

What is the difference between carburetors and fuel injectors?

Carburetors are older technology that mixes air and fuel outside the engine before delivery, while fuel injectors deliver fuel directly into the combustion chamber of the engine. Fuel injectors are more efficient, precise, and environmentally friendly compared to carburetors.

-

How can I prevent fuel injector problems?

To prevent fuel injector problems, it is essential to use high-quality fuel, perform regular maintenance on your vehicle, avoid running on low fuel levels, and follow the recommended service intervals for fuel system cleaning and inspection.