How Diesel Engines Handle Alaska’s Extreme Cold

Alaska's extreme cold presents a formidable challenge for diesel engines, pushing them to their limits in frigid temperatures that can plummet well below freezing. In such harsh conditions, the very essence of these engines is put to the test as they strive to endure and perform efficiently amidst the icy grip of winter.

Impact of Cold Temperatures on Diesel Engines

When it comes to diesel engines, extreme cold temperatures can pose significant challenges that impact their performance and reliability. Alaska's harsh winter conditions present unique obstacles for these engines, affecting various components and systems crucial for their operation. One of the primary issues faced by diesel engines in cold weather is fuel gelling, where the diesel fuel thickens and can clog fuel filters and lines, leading to engine stalling. Additionally, cold temperatures can reduce the efficiency of batteries, making it harder for engines to start. This combination of factors can result in difficulties in starting the engine and maintaining consistent performance.

To combat the negative effects of cold temperatures, diesel engines in Alaska are equipped with specialized features and components designed to enhance their cold-weather performance. Engine block heaters are commonly used to keep the engine warm and facilitate easier starts in freezing conditions. These heaters ensure that the engine oil and coolant remain at optimal temperatures, preventing issues such as oil thickening and promoting smoother operation during cold starts. Moreover, winterized fuel systems are implemented to prevent fuel gelling by incorporating additives that lower the fuel's freezing point, maintaining its flow and combustion efficiency even in extreme cold.

Considering the impact of cold temperatures on diesel engines, it is crucial for owners to adhere to specific maintenance practices to ensure the engines operate effectively in Alaska's winter climate. Regularly checking and replacing fuel filters is essential to prevent fuel gelling and maintain fuel system integrity. Keeping batteries fully charged and in good condition is also vital for reliable engine starts in cold weather. Additionally, using winter-grade diesel fuel with appropriate additives can further enhance engine performance and protect against cold-related issues.

Despite the challenges posed by cold temperatures, diesel engines in Alaska have demonstrated resilience and adaptability in extreme weather conditions. Through proper maintenance and the integration of cold-weather components, these engines continue to function reliably, powering various applications across the state. By understanding the impact of cold temperatures and implementing preventive measures, diesel engine owners can ensure optimal performance and longevity, even in the harshest winter environments.

Specialized Cold-Weather Components

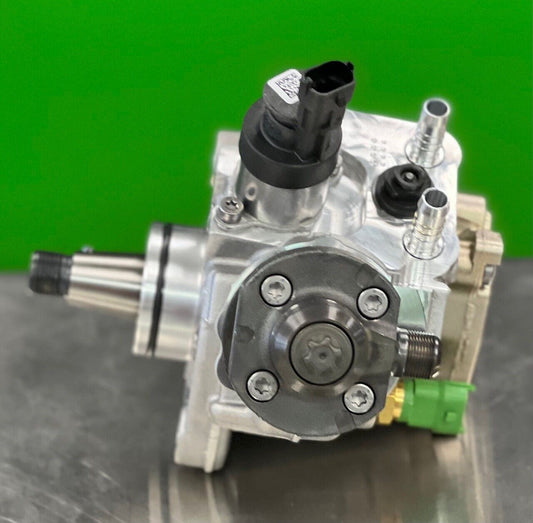

When it comes to facing the brutal cold of Alaska's winters, diesel engines are equipped with specialized components designed to withstand the extreme temperatures and ensure reliable performance. One crucial feature found in these engines is the winterized fuel system, which prevents fuel gelling that can occur in subzero conditions. This system includes fuel additives that lower the freezing point of diesel fuel, keeping it flowing smoothly even in the coldest weather.

In addition to the winterized fuel system, diesel engines in Alaska are often equipped with cold-start systems that assist in igniting the engine in frigid temperatures. These systems typically include glow plugs or intake air heaters that preheat the combustion chamber, making it easier for the engine to start in cold conditions. By providing the necessary heat for ignition, these components ensure that the engine can start reliably even when the mercury plummets.

Another essential component of cold-weather diesel engines is the engine block heater. This device warms the engine block overnight, maintaining a higher temperature that makes it easier to start the engine in the morning. By keeping the engine block warm, the block heater reduces wear on the engine components and improves overall efficiency, especially during the harsh winter months in Alaska.

Maintenance Tips for Cold-Weather Operation

When it comes to ensuring optimal performance of diesel engines in Alaska's cold winter conditions, maintenance plays a crucial role. The extreme cold temperatures can pose various challenges, but with proper care and attention, diesel engine owners can mitigate potential issues and ensure reliable operation throughout the winter months.

One essential maintenance tip for cold-weather operation is to regularly check and change the engine oil. In cold climates, the oil tends to thicken, making it harder for the engine to start. By using the manufacturer's recommended oil viscosity for cold temperatures and adhering to the prescribed oil change intervals, owners can help maintain the engine's lubrication properties and prevent unnecessary strain on the components.

In addition to oil changes, it is important to keep the fuel system well-maintained. Diesel fuel can gel in extremely cold temperatures, leading to fuel filter clogging and engine stalling. Using winterized diesel fuel and adding anti-gelling additives can prevent fuel gelling issues and ensure smooth engine performance even in sub-zero conditions.

Regularly inspecting and testing the battery is another vital maintenance tip for cold-weather operation. Cold weather can significantly reduce the battery's cranking power, making it challenging to start the engine. Ensuring the battery is in good condition, terminals are clean and connections are tight can help prevent starting problems and avoid being stranded in the cold.

Furthermore, maintaining the cooling system is crucial for diesel engines operating in cold climates. Checking the coolant level, condition, and concentration of antifreeze is essential to prevent the engine from overheating or freezing. Proper cooling system maintenance helps regulate the engine temperature and ensures efficient operation, especially during extreme cold snaps.

Lastly, don't overlook the importance of keeping the vehicle's exterior clean and free of snow and ice buildup. Snow and ice accumulation can obstruct airflow to the engine, affecting performance and fuel efficiency. Regularly clearing snow from the grille, hood, and around the exhaust can help prevent overheating and ensure the engine operates optimally in the harsh winter conditions of Alaska.

Case Studies of Diesel Engine Performance in Alaska

When it comes to assessing the performance of diesel engines in Alaska's unforgiving winter conditions, real-life case studies provide invaluable insights into the challenges faced and the solutions implemented. These case studies serve as a testament to the resilience and adaptability of diesel engines in extreme cold climates. Let's delve into some noteworthy examples that showcase the prowess of these engines in Alaska's harsh environment.

One compelling case study involves a fleet of commercial trucks operating in remote areas of Alaska where temperatures can plummet well below freezing. Despite facing subzero temperatures and challenging terrain, these diesel engines have demonstrated remarkable durability and reliability. Through strategic maintenance practices and the use of specialized cold-weather components, such as block heaters and winterized fuel systems, these trucks have been able to navigate the icy roads and deliver goods efficiently.

Another fascinating case study revolves around a diesel generator powering a remote Alaskan community during the winter months. This generator plays a critical role in providing electricity to residents in isolated areas where conventional power sources are scarce. Despite the extreme cold and harsh weather conditions, the diesel engine has proven to be a lifeline for the community, ensuring uninterrupted power supply even in the face of blizzards and snowstorms.

Moreover, a research study conducted on the performance of diesel engines in Alaska's cold climate revealed the importance of regular maintenance and proper winterization techniques. By implementing preventive measures such as using cold-weather additives in fuel and ensuring adequate insulation for engine components, the study highlighted significant improvements in engine efficiency and longevity.

These case studies underscore the critical role that diesel engines play in Alaska's infrastructure and economy, powering transportation, energy generation, and various industrial operations in the face of extreme cold. By showcasing the successful adaptation of diesel engines to the challenges of Alaska's winter conditions, these real-world examples inspire confidence in the reliability and performance of these engines in the harshest environments.

Future Innovations in Cold-Weather Diesel Engine Technology

As we gaze into the future of diesel engine technology in the context of Alaska's frigid environment, innovation becomes the guiding star illuminating the path towards enhanced performance and efficiency. Picture a scenario where diesel engines are not just surviving but thriving in the icy embrace of Alaska's winters, thanks to groundbreaking advancements in cold-weather engineering.

One of the key areas of focus for future innovations lies in the development of advanced heating systems that can rapidly warm up the engine components, ensuring a swift and smooth start even in the most bone-chilling temperatures. Imagine engines equipped with intelligent heating elements that preemptively adjust their operation based on real-time temperature data, much like a well-prepared athlete adjusting their strategy to conquer a challenging opponent.

Furthermore, enhanced insulation materials are poised to revolutionize the way diesel engines combat the cold. Imagine engines cocooned in cutting-edge insulating layers that keep vital components at optimal operating temperatures, akin to a cozy blanket shielding a sleeper from the winter chill.

Additionally, smart sensors and predictive analytics are set to play a pivotal role in the evolution of cold-weather diesel engine technology. Envision engines equipped with sensors that not only detect potential issues before they escalate but also proactively suggest maintenance actions, akin to a vigilant guardian foreseeing and averting impending threats.

Collaborations between automotive engineers and materials scientists are paving the way for the development of nanotechnology-infused components that exhibit unparalleled resilience in extreme cold. Picture engines incorporating nanomaterials that defy the conventional limitations of temperature, akin to a superhero donning an indestructible suit to combat the forces of nature.

In conclusion, the future of cold-weather diesel engine technology in Alaska is a realm where imagination meets ingenuity, where challenges are viewed as opportunities for innovation rather than obstacles. With each leap forward in technological prowess, diesel engines are poised to not only withstand but conquer the icy trials of Alaska's winters, ushering in a new era of performance and reliability in the face of extreme cold.

Frequently Asked Questions

-

How do diesel engines perform in extreme cold conditions?

Diesel engines are specifically designed to handle harsh winter environments, such as those found in Alaska. They are equipped with features like block heaters and winterized fuel systems to ensure reliable performance even in freezing temperatures.

-

What is fuel gelling and how does it affect diesel engines?

Fuel gelling occurs when diesel fuel solidifies in cold temperatures, clogging fuel filters and impeding engine operation. To prevent this, diesel engines in Alaska use special additives and fuel heaters to keep the fuel flowing smoothly.

-

Why is maintenance crucial for diesel engines in cold weather?

Maintaining diesel engines in Alaska during winter is essential to prevent issues like frozen fuel lines and battery failure. Regular maintenance, including checking coolant levels and battery condition, is vital for optimal performance.

-

How do cold-start systems help diesel engines in extreme cold?

Cold-start systems in diesel engines are designed to preheat the engine block and fuel system, making it easier to start the engine in freezing temperatures. These systems reduce wear on the engine and ensure smoother operation during cold starts.

-

What are some tips for improving diesel engine performance in Alaska's winter?

Owners of diesel engines in Alaska can enhance cold-weather performance by using winter-grade diesel fuel, keeping batteries charged, and parking vehicles in sheltered areas to minimize exposure to extreme cold.