How to Improve Diesel Engine Efficiency in Arizona’s Desert Heat

Arizona's scorching desert heat poses a significant challenge to the efficiency and performance of diesel engines. The extreme temperatures can push these engines to their limits, leading to decreased efficiency and potential breakdowns if not properly managed. To combat these challenges and ensure optimal functioning, it is crucial to implement a combination of strategies and technologies specifically tailored to enhance diesel engine performance in Arizona's desert climate.

Importance of Proper Maintenance

The cannot be overstated when it comes to ensuring the longevity and efficiency of diesel engines in the scorching heat of Arizona's desert climate. Regular maintenance practices play a vital role in keeping the engine running smoothly and preventing unexpected breakdowns that could leave you stranded in the unforgiving desert terrain.

By adhering to a strict maintenance schedule, you can proactively address potential issues before they escalate into costly problems. This includes regular oil changes, filter replacements, and thorough inspections to identify any wear and tear that may compromise the engine's performance under extreme temperatures.

Moreover, proper maintenance not only optimizes the engine's efficiency but also contributes to its overall durability. Just like a well-oiled machine, a well-maintained diesel engine can withstand the harsh conditions of the desert heat without breaking a sweat. Neglecting maintenance, on the other hand, is akin to inviting trouble to knock on your engine's door.

Imagine your diesel engine as a finely tuned instrument that requires regular tuning and adjustments to deliver its best performance. Without proper care and attention, even the most robust engines can succumb to the relentless heat of the Arizona desert. It's like expecting a marathon runner to finish a race without adequate training and preparation – a recipe for disaster.

Furthermore, neglecting maintenance can lead to inefficient fuel consumption and reduced power output, diminishing the engine's overall performance. In the scorching heat of the desert, every drop of fuel counts, and a well-maintained engine can make all the difference between reaching your destination smoothly or being stranded in the blistering sun.

In essence, proper maintenance is the lifeblood of diesel engines operating in Arizona's desert heat. It is the foundation on which optimal performance, efficiency, and reliability are built. By prioritizing regular maintenance practices, you not only safeguard your engine against unexpected failures but also ensure that it continues to operate at its peak, conquering the challenges of the desert with ease.

Utilizing Advanced Cooling Systems

When it comes to enhancing the performance of diesel engines in the scorching heat of Arizona's desert climate, utilizing advanced cooling systems is paramount. These innovative technologies play a crucial role in managing the engine temperature and improving overall efficiency, ensuring that the engine operates optimally even in extreme conditions.

One of the key strategies in utilizing advanced cooling systems is the integration of high-efficiency radiators and cooling fans. These components work together to dissipate heat effectively, preventing the engine from overheating and maintaining a stable operating temperature. By keeping the engine cool, these systems help prevent performance degradation and potential damage due to excessive heat.

In addition to traditional cooling methods, modern diesel engines can benefit from advanced liquid cooling systems that utilize cutting-edge technology to regulate temperature more efficiently. These systems often incorporate sensors and control mechanisms to adjust cooling levels based on real-time data, ensuring optimal performance under varying load and temperature conditions.

Furthermore, the use of thermal management solutions, such as heat exchangers and coolant additives, can significantly improve the cooling efficiency of diesel engines in hot environments. These advanced cooling technologies help maximize heat transfer and maintain consistent temperatures throughout the engine, enhancing overall performance and longevity.

Optimizing Fuel Combustion

Optimizing fuel combustion in diesel engines under the scorching Arizona desert sun is crucial for achieving peak performance and efficiency. The extreme heat can pose challenges, making it essential to fine-tune combustion processes to ensure the engine operates at its best. One effective strategy is to adjust the fuel injection timing and optimize the air-fuel mixture for maximum efficiency. By precisely controlling these parameters, the engine can generate more power while consuming less fuel, a win-win situation for both performance and economy.

Furthermore, utilizing high-quality fuel additives can significantly enhance combustion efficiency in diesel engines. These additives are designed to improve fuel atomization, combustion stability, and overall engine cleanliness. By incorporating additives that promote better combustion, diesel engines can operate more smoothly and efficiently, even in the harsh desert conditions of Arizona. This approach not only optimizes fuel combustion but also helps maintain the engine's longevity and reliability.

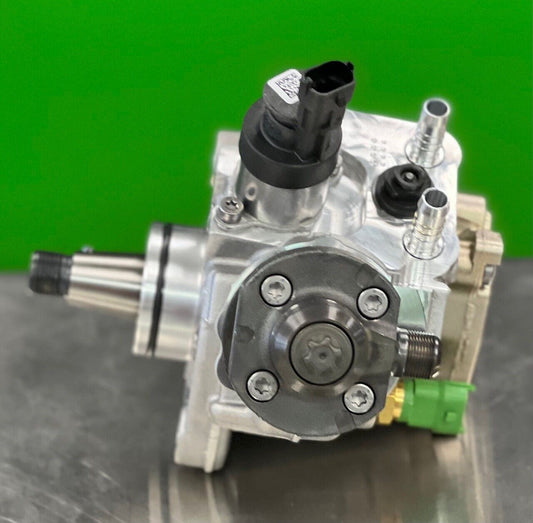

Another essential aspect of optimizing fuel combustion is ensuring proper maintenance of the engine's fuel system. Regularly inspecting and cleaning fuel injectors, filters, and pumps is vital for efficient combustion. Any clogs or malfunctions in the fuel system can disrupt the combustion process, leading to decreased performance and increased fuel consumption. By keeping the fuel system in top condition, diesel engines can operate at their peak efficiency levels, delivering optimal power output without unnecessary waste.

In addition to these strategies, considering the quality and type of fuel used can also impact combustion efficiency in diesel engines. Using high-grade diesel fuel with the right cetane rating and low sulfur content can promote cleaner and more efficient combustion. Low-quality fuel can leave deposits in the engine, affecting combustion and overall performance. Therefore, investing in premium diesel fuel can contribute to better combustion efficiency and prolonged engine life, especially in the demanding conditions of the Arizona desert.

Enhancing Air Intake Systems

When it comes to enhancing air intake systems for diesel engines operating in the scorching heat of Arizona's desert, one must pay close attention to the intricate details that can make a significant difference in performance. The air intake system plays a crucial role in ensuring the engine receives clean, cool air for combustion, which is vital for efficiency in such extreme conditions.

One effective strategy for improving air intake systems is to incorporate advanced air filters that can efficiently remove dust, sand, and other particulate matter commonly found in desert environments. These filters not only help in maintaining the quality of air entering the engine but also prevent potential damage from debris, ultimately extending the engine's lifespan.

Moreover, optimizing the air intake pathway by reducing restrictions and ensuring smooth airflow can significantly enhance the engine's efficiency. By minimizing turbulence and pressure drops in the intake system, the engine can operate more smoothly and effectively, translating to improved overall performance.

Additionally, considering the installation of air-to-air intercoolers can be beneficial in cooling the intake air before it enters the engine. This technology helps in lowering the temperature of the air, increasing its density, and consequently improving combustion efficiency, especially crucial in the desert heat where high temperatures can impact engine performance.

Furthermore, regular inspection and maintenance of air intake components, such as hoses, connections, and seals, are essential to prevent any leaks or damages that could compromise the system's effectiveness. Ensuring that all parts are in optimal condition guarantees that the engine receives the necessary airflow without any disruptions.

In conclusion, enhancing air intake systems for diesel engines in Arizona's desert heat requires a comprehensive approach that focuses on cleanliness, airflow optimization, and maintenance. By investing in advanced filters, optimizing airflow pathways, considering intercooling technologies, and prioritizing regular upkeep, one can significantly boost the efficiency and longevity of diesel engines operating in such challenging environmental conditions.

Exploring Alternative Fuel Options

When it comes to exploring alternative fuel options for diesel engines in Arizona's desert heat, the possibilities are as vast as the landscape itself. One promising alternative is biodiesel, which is derived from renewable sources such as vegetable oils and animal fats. Biodiesel not only reduces greenhouse gas emissions but also offers a cleaner burning fuel option for diesel engines, making it a sustainable choice for the environmentally conscious.

Another alternative fuel worth considering is synthetic diesel, which is produced through a process that converts natural gas or biomass into a high-quality diesel fuel. Synthetic diesel has the advantage of being more energy-efficient than traditional diesel, leading to improved engine performance and reduced emissions. Its high cetane rating also ensures a smoother combustion process, ideal for enhancing efficiency in extreme desert conditions.

Furthermore, exploring the use of hydrogen as a fuel source holds great potential for diesel engines operating in the Arizona desert. Hydrogen fuel cells produce electricity through a chemical reaction with hydrogen, emitting only water vapor and heat as byproducts. This clean energy source not only reduces harmful emissions but also offers a sustainable solution for enhancing engine efficiency in the desert heat.

Considering the unique challenges posed by Arizona's desert climate, the exploration of alternative fuel options becomes crucial in optimizing diesel engine performance and efficiency. By embracing innovative fuel sources that prioritize sustainability and efficiency, diesel engine operators can navigate the desert terrain with confidence, knowing they are contributing to a greener and more efficient future.

Frequently Asked Questions

-

What are the common challenges faced by diesel engines in Arizona's desert heat?

Diesel engines in Arizona's desert heat often encounter issues with overheating, decreased efficiency, and increased wear and tear due to the extreme temperatures. These challenges can impact the overall performance and longevity of the engine if not properly addressed.

-

How frequently should diesel engines in hot desert environments be maintained?

Regular maintenance is crucial for diesel engines operating in hot desert environments. It is recommended to follow a strict maintenance schedule, including oil changes, filter replacements, and cooling system checks, to ensure optimal performance and efficiency in such harsh conditions.

-

What role do cooling systems play in improving diesel engine efficiency in the desert?

Cooling systems are essential for managing engine temperature and preventing overheating in the desert heat. Advanced cooling technologies help regulate the engine's temperature, ensuring efficient operation and minimizing the risk of breakdowns due to heat-related issues.

-

How can optimizing fuel combustion enhance diesel engine performance in hot climates?

By optimizing fuel combustion, diesel engines can achieve better efficiency and performance in hot desert climates. Strategies such as proper fuel injection timing and maintaining the right air-fuel ratio can significantly improve overall engine operation in extreme heat.

-

Are alternative fuel options viable for improving diesel engine efficiency in Arizona's desert?

Exploring alternative fuel sources can offer potential benefits for diesel engines in Arizona's desert heat. Alternative fuels like biodiesel or synthetic diesel blends may provide improved combustion characteristics and reduced emissions, contributing to enhanced engine efficiency.