How to Replace Diesel Engine Parts in Florida’s Humid Climate

Replacing diesel engine parts in Florida's humid climate requires careful consideration and specific actions to ensure the longevity and optimal performance of the engine. The high humidity levels in Florida can pose challenges to diesel engines, such as corrosion, rust, and reduced efficiency. To combat these issues, it is essential to choose the right parts, perform regular maintenance, and take necessary precautions.

When selecting diesel engine parts for Florida's climate, it is crucial to opt for components that are durable and corrosion-resistant. These parts should be able to withstand the humid conditions prevalent in the state, preventing damage and ensuring the smooth operation of the engine. Choosing high-quality parts will contribute to the overall performance and lifespan of the diesel engine.

Proper maintenance and precautions are key to preserving diesel engine parts in a high humidity environment. Regular checks for corrosion, rust, and any signs of wear are essential to prevent potential damage. Additionally, keeping the engine clean and dry, using appropriate lubricants, and storing the engine in a controlled environment can help mitigate the effects of humidity on the parts.

When it comes to replacing diesel engine parts in Florida's humid climate, following a step-by-step approach is crucial. Begin by identifying the parts that need replacement and ensuring you have the necessary tools for the job. Take safety measures seriously, such as wearing protective gear and working in a well-ventilated area. By following best practices and guidelines, you can effectively replace engine parts without compromising safety or performance.

Seeking professional assistance for diesel engine maintenance in Florida is advisable, especially for complex replacements or repairs. Professional mechanics have the expertise and resources to handle engine maintenance in high humidity environments effectively. By partnering with experts, you can ensure that your diesel engine receives the care it needs to operate efficiently and reliably in Florida's climate.

Understanding the Impact of Humidity on Diesel Engines

Humidity plays a significant role in the performance and longevity of diesel engines, especially in the unique climate of Florida. The high levels of moisture in the air can lead to various challenges for diesel engine parts, impacting their functionality and durability. One of the primary issues caused by humidity is corrosion, which can affect crucial components of the engine, such as the fuel system and exhaust system. Additionally, the presence of moisture in the air can accelerate the process of rust formation on metal surfaces, further compromising the efficiency of the engine.

Furthermore, the combination of heat and humidity in Florida's climate can contribute to the degradation of rubber seals and gaskets within the engine. These seals are essential for maintaining proper compression and preventing leaks, but they can deteriorate more rapidly in a humid environment. As a result, the overall performance of the diesel engine may be compromised, leading to decreased fuel efficiency and potential mechanical issues.

In addition to corrosion and rubber seal degradation, high humidity levels can also impact the air intake system of diesel engines. The presence of moisture in the air can lead to the formation of condensation within the intake system, affecting the combustion process and potentially causing engine misfires or rough idling. This highlights the importance of understanding how humidity can influence the various components of a diesel engine and the need for proactive maintenance and care.

Choosing the Right Diesel Engine Parts for Florida’s Climate

When it comes to choosing the right diesel engine parts for Florida's humid climate, one must consider various factors to ensure optimal performance and longevity. The high humidity levels in Florida can accelerate corrosion and rust on engine parts, leading to potential issues with the engine's efficiency and durability. Therefore, selecting durable and corrosion-resistant parts is crucial in maintaining the engine's functionality in such conditions.

One key consideration when choosing diesel engine parts for Florida's climate is the material they are made of. Opting for materials like stainless steel or aluminum can provide better resistance to corrosion caused by the humid environment. These materials are known for their durability and ability to withstand the harsh conditions prevalent in Florida.

Additionally, it is essential to select parts that are specifically designed for use in high humidity environments. These parts are typically coated or treated to provide an extra layer of protection against moisture and humidity, ensuring they remain in optimal condition even in the face of challenging weather conditions.

Furthermore, when choosing diesel engine parts for Florida, it is advisable to consult with experts or professionals in the field. They can offer valuable insights and recommendations based on their experience working with engines in similar climates. Their expertise can help you make informed decisions and select the most suitable parts for your specific engine and operating conditions.

Precautions and Maintenance Tips for Diesel Engines in High Humidity

When operating diesel engines in Florida's high humidity, it is crucial to implement a set of precautions and maintenance tips to mitigate the adverse effects of the moist environment. One key precaution is to regularly check and replace air filters to prevent moisture from entering the engine, which can lead to corrosion and reduced performance. Additionally, using high-quality fuel filters can help safeguard the engine from contaminants that may be more prevalent in humid conditions.

Another essential maintenance tip is to inspect and clean the cooling system regularly. The radiator and cooling fins should be free of debris and dirt to ensure optimal heat dissipation, especially in the humid climate of Florida where engines are prone to overheating. Proper coolant levels should be maintained to prevent engine overheating and potential damage.

Furthermore, it is advisable to conduct frequent inspections of electrical components such as wiring and connectors. Moisture can cause electrical connections to corrode, leading to malfunctions and potential safety hazards. Applying a protective coating or using dielectric grease on electrical connections can help prevent corrosion and ensure reliable engine operation.

Regularly checking and maintaining the battery is also crucial in high humidity conditions. The battery terminals should be clean and free of corrosion to ensure a strong electrical connection. Additionally, keeping the battery securely mounted can prevent vibrations that may lead to damage or premature wear.

In addition to these precautions and maintenance tips, it is recommended to store diesel engines in a dry and well-ventilated area when not in use. This can help prevent moisture buildup and corrosion, extending the lifespan of engine parts and ensuring consistent performance in Florida's humid climate.

Replacing Diesel Engine Parts in a Humid Environment

When it comes to replacing diesel engine parts in a humid environment like Florida, it's crucial to be meticulous and thorough in your approach. The high humidity levels can significantly impact the performance and longevity of engine parts, making proper replacement procedures essential for optimal functioning. Before diving into the replacement process, it's important to assess the condition of the existing parts and identify any signs of wear or damage caused by the humid climate.

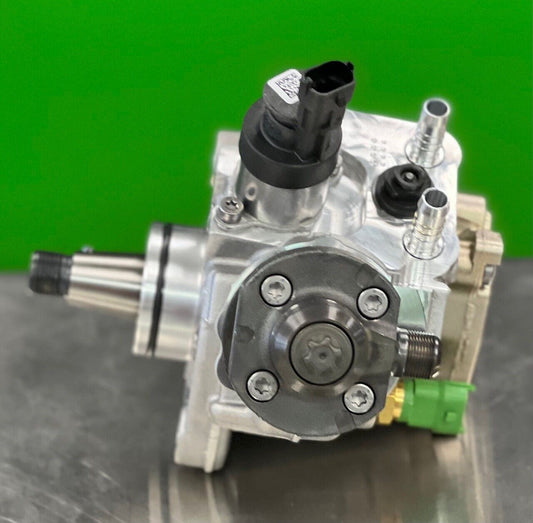

One key aspect to consider when replacing diesel engine parts in a humid environment is the selection of high-quality, corrosion-resistant components. Choosing parts specifically designed to withstand the challenges posed by humidity can help prevent premature deterioration and ensure long-term reliability. Additionally, ensuring a proper fit and compatibility with your engine model is essential to avoid any complications during installation.

Before initiating the replacement process, gather all the necessary tools and equipment required for the task. This may include wrenches, sockets, screwdrivers, and any specialized tools needed for specific engine parts. It's also advisable to work in a well-ventilated area to prevent the accumulation of moisture, which can further exacerbate the effects of humidity on the engine components.

When removing the old parts, take care to follow the manufacturer's guidelines and recommended procedures to avoid causing any damage to surrounding components. Inspect the replacement parts carefully before installation to ensure they are free of defects and damage. Proper handling and storage of the new parts are crucial to maintaining their integrity and performance.

During the replacement process, pay close attention to the details and follow a systematic approach to avoid errors or omissions. Double-check each step to ensure proper alignment and secure installation of the new parts. Tighten fasteners to the specified torque values to prevent loosening or over-tightening, which can lead to issues down the line.

Once the replacement is complete, conduct a thorough inspection of the engine to verify that all components are securely in place and functioning correctly. Start the engine and listen for any unusual noises or vibrations that may indicate improper installation. Monitor the engine performance closely in the initial stages after replacement to detect any potential issues early on.

In conclusion, replacing diesel engine parts in a humid environment requires attention to detail, careful planning, and adherence to best practices. By selecting quality parts, following proper procedures, and conducting thorough inspections, you can ensure the longevity and efficiency of your engine in Florida's challenging climate.

Professional Assistance and Resources for Diesel Engine Maintenance

When it comes to maintaining diesel engines in Florida's humid climate, seeking professional assistance and utilizing resources can make a significant difference in the performance and longevity of engine parts. Professional assistance can range from consulting with experienced mechanics to hiring specialized technicians who understand the unique challenges posed by high humidity.

One valuable resource for diesel engine maintenance in humid environments is access to genuine parts and components that are specifically designed to withstand the corrosive effects of moisture in the air. These parts are often more durable and resistant to rust, ensuring that your engine operates smoothly even in the most challenging conditions.

Additionally, joining online forums or communities dedicated to diesel engine maintenance can provide a wealth of knowledge and support. Engaging with fellow enthusiasts and experts can offer valuable insights, tips, and troubleshooting advice for maintaining your diesel engine in Florida's humid climate.

Another essential aspect of professional assistance is regular inspections and maintenance checks conducted by certified technicians. These professionals can identify potential issues early on, perform necessary repairs, and offer preventive maintenance measures to keep your diesel engine running efficiently in the face of high humidity.

Lastly, investing in proper storage and maintenance facilities for your diesel engine can also be considered a form of professional assistance. Storing your engine in a dry and well-ventilated environment when not in use can help prevent moisture-related damage and extend the lifespan of engine parts, ultimately saving you time and money in the long run.

Frequently Asked Questions

-

Q: What are the common issues faced by diesel engines in Florida's humid climate?

A: Diesel engines in Florida's humid climate often encounter challenges such as corrosion, rust, and decreased performance due to the moisture levels in the air.

-

Q: How can I choose the right diesel engine parts for Florida's humid climate?

A: It is essential to select durable and corrosion-resistant diesel engine parts specifically designed to withstand the high humidity in Florida. Opt for parts made from materials that offer protection against rust and corrosion.

-

Q: What precautions should I take when maintaining diesel engines in a humid environment?

A: When maintaining diesel engines in high humidity, it is crucial to regularly inspect for signs of corrosion, keep the engine dry, and use appropriate lubricants to prevent moisture-related damage. Additionally, storing spare parts in a dry environment can help prolong their lifespan.

-

Q: Is professional assistance necessary for replacing diesel engine parts in Florida's humid climate?

A: While some replacements can be done independently, seeking professional assistance for complex part replacements in a humid environment is advisable to ensure the job is done correctly and to prevent further damage to the engine.

-

Q: Where can I find resources for diesel engine maintenance in Florida?

A: Resources for diesel engine maintenance in Florida, such as specialized workshops, online forums, and manufacturer guidelines, can provide valuable information on best practices, maintenance tips, and where to source quality parts suitable for the humid climate.