Common Diesel Engine Issues and How to Fix Them in Arizona

Arizona's unique climate can pose specific challenges for diesel engines, leading to various issues that require prompt attention and effective solutions. Understanding the common problems faced by diesel engines in this region is crucial for maintaining optimal performance and prolonging the lifespan of these powerful machines.

Overheating Engines

When it comes to diesel engines in Arizona, overheating can be a major concern that needs immediate attention. The scorching temperatures in the state can put a significant strain on the engine, leading to overheating issues. One common cause of overheating in diesel engines is a malfunctioning cooling system. The extreme heat in Arizona can make it challenging for the cooling system to regulate the engine temperature effectively. Additionally, low coolant levels or a faulty thermostat can also contribute to overheating problems. To prevent overheating, it is crucial to regularly check the coolant levels and ensure that the cooling system is functioning correctly.

If your diesel engine is overheating in Arizona, there are several steps you can take to address the issue promptly. Firstly, it is essential to pull over and allow the engine to cool down before continuing to drive. Continuing to operate an overheating engine can cause severe damage and lead to costly repairs. Once the engine has cooled down, you can check the coolant levels and inspect the cooling system for any leaks or malfunctions. If you are unable to identify the cause of the overheating, it is advisable to seek professional help to diagnose and repair the issue effectively.

Regular maintenance of the cooling system is key to preventing overheating problems in diesel engines in Arizona. This includes flushing the cooling system, checking for leaks, and replacing the coolant as recommended by the manufacturer. In addition, monitoring the engine temperature gauge while driving can help you detect any early signs of overheating and take appropriate action. By staying proactive and addressing overheating issues promptly, you can ensure the optimal performance and longevity of your diesel engine in the Arizona climate.

Injector Problems

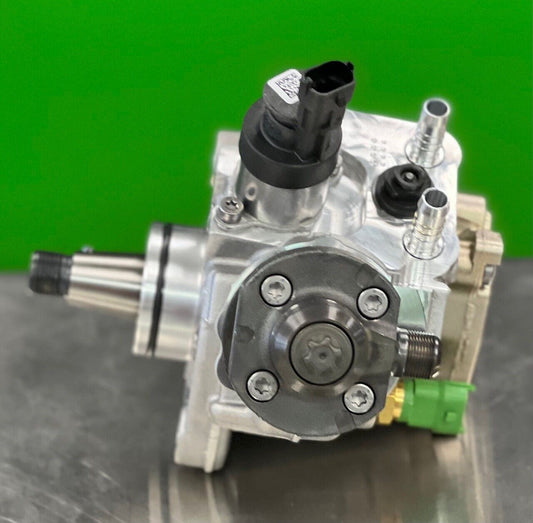

When it comes to diesel engines in Arizona, injector problems can be a significant issue that affects performance and efficiency. Prompt and accurate diagnosis is crucial in addressing injector problems effectively. Injectors play a vital role in the engine's combustion process, and any malfunction can lead to poor fuel economy, rough idling, or even engine misfires. Applying proper maintenance routines and regular inspections can help prevent injector problems from escalating and causing further damage to the engine.

One common injector issue in diesel engines is clogging or blockage, often caused by impurities in the fuel or inadequate filtration. These blockages can disrupt the fuel flow and affect the injector's spray pattern, leading to incomplete combustion and reduced engine power. Regularly checking and cleaning the injectors can help prevent clogs and ensure smooth fuel delivery. Additionally, using high-quality fuel and installing effective fuel filters can minimize the risk of injector problems.

Another common injector problem is injector leakage, where fuel leaks from the injector nozzles or seals. This can result in fuel wastage, increased emissions, and potentially hazardous situations. Identifying the source of the leakage and promptly replacing faulty injectors or seals is essential to maintain the engine's performance and prevent fuel-related issues. Properly torquing the injector nozzles and ensuring a secure fit can help prevent leakage and ensure efficient fuel delivery.

In some cases, injector problems may also arise from electrical issues, such as faulty wiring or connector problems. These electrical faults can disrupt the injector's signal or control, leading to irregular fuel injection and engine performance issues. Conducting thorough electrical diagnostics and checking the injector wiring for any damage or loose connections can help identify and resolve these issues. Ensuring proper grounding and insulation of the electrical components can prevent injector problems caused by electrical failures.

Overall, addressing injector problems in diesel engines requires a combination of preventative maintenance, regular inspections, and timely repairs. By staying vigilant and proactive in monitoring the injectors' performance, diesel engine owners in Arizona can prevent potential injector issues and ensure optimal engine operation. Remember, a well-maintained injector system is key to maximizing fuel efficiency and prolonging the engine's lifespan.

Dirty Fuel Filters

When it comes to diesel engines in Arizona, dirty fuel filters can pose a significant threat to their performance and longevity. Fuel filters play a crucial role in ensuring that the fuel entering the engine is clean and free from contaminants. However, in the dusty and hot climate of Arizona, these filters can quickly become clogged with debris, dirt, and other particles, leading to a range of issues.

Dirty fuel filters can restrict the flow of fuel to the engine, causing it to run inefficiently and potentially leading to stalling or rough idling. This can not only affect the engine's performance but also result in decreased fuel efficiency and increased emissions. Moreover, if left unchecked, dirty fuel filters can eventually cause damage to other engine components, leading to costly repairs.

To address dirty fuel filter problems in diesel engines in Arizona, regular maintenance is key. It is essential to follow the manufacturer's guidelines for filter replacement intervals and ensure that filters are changed promptly when needed. Additionally, using high-quality fuel and regularly inspecting the filters for any signs of dirt or clogging can help prevent issues before they escalate.

When faced with symptoms of a dirty fuel filter, such as engine misfires or reduced power, it is crucial to address the issue promptly. Ignoring the problem can lead to more severe engine damage and potentially leave you stranded on the side of the road. By staying proactive and attentive to the condition of your fuel filters, you can ensure that your diesel engine performs optimally and remains reliable in the challenging Arizona environment.

Electrical System Failures

When it comes to diesel engines in Arizona, one of the significant issues that can arise is electrical system failures. Imagine your engine as a complex network of electrical connections, each playing a crucial role in the overall performance. Now, picture the chaos that can ensue when even a single component fails to function correctly. It's like a domino effect, where one small disruption can lead to a series of malfunctions.

Common causes of electrical system failures in diesel engines include faulty wiring, corroded connections, or malfunctioning components. Just like a chain is only as strong as its weakest link, an electrical system is only as reliable as its most vulnerable part. Therefore, diagnosing and addressing these failures promptly is essential to prevent further damage and ensure the smooth operation of your engine.

When faced with electrical system issues, it's crucial to perform a comprehensive inspection to identify the root cause. Think of it as detective work, where you need to follow the clues provided by the symptoms exhibited by your engine. Is there a sudden loss of power? Are there warning lights flashing on your dashboard? These are all indicators that something might be amiss in the electrical system.

Once you've pinpointed the source of the problem, it's time to take action. This could involve repairing or replacing damaged wires, cleaning corroded connections, or installing new components. It's like giving your engine a fresh set of batteries to power through any obstacles in its way.

Regular maintenance and inspections can also help prevent electrical system failures before they occur. By keeping your engine's electrical components clean, dry, and well-maintained, you can minimize the risk of unexpected breakdowns. It's like giving your engine a protective shield against the harsh Arizona climate and ensuring its longevity.

Exhaust System Troubles

When it comes to diesel engines in Arizona, one of the common issues that can arise is related to the exhaust system. The extreme heat and dusty conditions in Arizona can put a strain on the exhaust system of diesel engines, leading to potential troubles that need to be addressed promptly. The exhaust system plays a crucial role in managing emissions and ensuring the engine runs smoothly, so any issues in this area can have a significant impact on overall performance.

One of the primary exhaust system troubles that diesel engines in Arizona may face is clogging or blockages in the exhaust pipes or muffler. These blockages can restrict the flow of exhaust gases, leading to increased back pressure and potential damage to the engine. To prevent this issue, regular inspection and maintenance of the exhaust system are essential. Checking for any signs of blockages, such as unusual noises or reduced engine power, can help in identifying and resolving potential problems before they escalate.

In addition to blockages, diesel engines in Arizona may also experience issues with exhaust leaks. These leaks can occur due to corrosion or damage to the exhaust system components, such as the exhaust manifold or gaskets. When left unaddressed, exhaust leaks can not only affect engine performance but also pose a safety risk due to the release of harmful gases. It is crucial to inspect the exhaust system regularly for any signs of leaks and repair them promptly to ensure the engine operates efficiently and safely.

Moreover, another common exhaust system trouble in diesel engines is the buildup of soot and carbon deposits. The hot and dusty conditions in Arizona can accelerate the accumulation of soot in the exhaust system, leading to reduced efficiency and increased emissions. Regular cleaning of the exhaust system, including the diesel particulate filter, can help prevent excessive buildup and maintain optimal performance. Proper maintenance practices, such as using high-quality fuel and additives, can also aid in reducing soot formation and extending the lifespan of the exhaust system components.

Overall, addressing exhaust system troubles in diesel engines in Arizona requires proactive maintenance and timely repairs to ensure optimal performance and longevity. By staying vigilant and conducting regular inspections, diesel engine owners can mitigate potential issues related to the exhaust system and enjoy reliable operation in the challenging Arizona climate.

Frequently Asked Questions

-

What are the common signs of an overheating diesel engine in Arizona?

Common signs of an overheating diesel engine in Arizona include rising temperature gauges, steam coming from the engine, and a strong smell of burning coolant. If you notice any of these signs, it is essential to address the issue promptly to prevent further damage to the engine.

-

How can I prevent injector problems in my diesel engine in the Arizona climate?

To prevent injector problems in your diesel engine in Arizona, it is crucial to use high-quality fuel, perform regular maintenance checks, and ensure proper fuel filtration. Additionally, avoiding prolonged idling and using fuel additives can help maintain the injectors' optimal performance.

-

What are the consequences of neglecting dirty fuel filters in a diesel engine in Arizona?

Neglecting dirty fuel filters in a diesel engine in Arizona can lead to reduced engine performance, decreased fuel efficiency, and potential engine damage. Regularly replacing and maintaining clean fuel filters is essential to ensure the smooth operation of your diesel engine.

-

How can I diagnose electrical system failures in my diesel engine in Arizona?

Diagnosing electrical system failures in a diesel engine in Arizona involves checking for blown fuses, loose connections, and testing the battery and alternator. Utilizing diagnostic tools and seeking professional assistance can help identify and address electrical issues effectively.

-

What maintenance practices can help prevent exhaust system troubles in diesel engines in Arizona?

Maintaining proper exhaust system function in diesel engines in Arizona involves regular inspection for leaks, corrosion, and damaged components. Additionally, ensuring timely repairs, using high-quality exhaust parts, and following manufacturer recommendations can help prevent exhaust system troubles.