LB7 Injector Troubleshooting Tips

When it comes to troubleshooting LB7 injectors, there are several key tips to keep in mind to effectively diagnose and resolve issues. From identifying common symptoms to utilizing diagnostic tools and following proper repair guidelines, these tips are essential for maintaining optimal performance. Let's dive into the details to ensure your LB7 injectors are in top condition.

First and foremost, prompt action is crucial when you notice any irregularities in your vehicle's performance. Whether it's rough idling, excessive smoke, or a loss of power, these could be signs of injector problems. By addressing these issues early on, you can prevent further damage and costly repairs down the line.

One effective approach is to apply troubleshooting techniques to the entire list of symptoms you observe. By systematically analyzing each symptom and its potential causes, you can narrow down the root of the problem and take targeted action. This methodical approach can save time and effort in the long run.

Utilizing diagnostic tools is another important aspect of troubleshooting LB7 injectors. From scan tools to fuel pressure gauges, these tools can provide valuable insights into the performance of your injectors. Additionally, monitoring injector balance rates can help identify any discrepancies that may indicate underlying issues.

Creating a comprehensive checklist of diagnostic steps can streamline the troubleshooting process. By systematically following each step and recording the results, you can track your progress and ensure thorough testing. This organized approach can help you identify the problem accurately and expedite the resolution process.

Remember, preventive maintenance is key to avoiding injector problems in the first place. Regularly inspecting and servicing your injectors, along with implementing proactive maintenance practices, can significantly extend their lifespan and performance. By staying proactive and attentive to your vehicle's needs, you can ensure smooth operation and longevity for your LB7 injectors.

Understanding LB7 Injectors

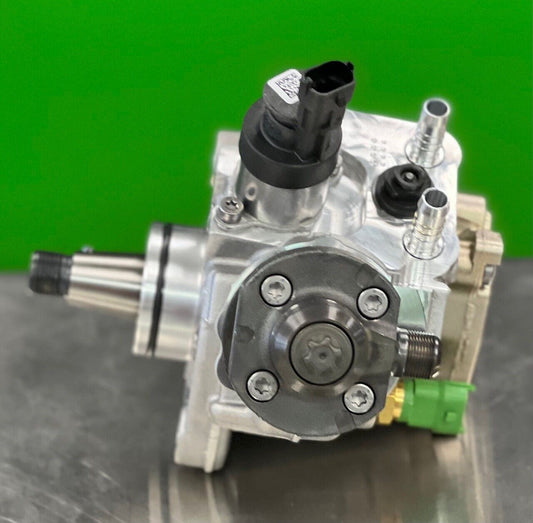

LB7 injectors are vital components found in Duramax engines, playing a crucial role in the fuel delivery process to the combustion chamber. Imagine them as the precision artists of your engine, carefully orchestrating the fuel injection to ensure optimal performance. These injectors are designed to deliver the right amount of fuel at the precise moment, contributing to the smooth operation and power of your vehicle.

When it comes to understanding LB7 injectors, it's essential to grasp their intricate mechanics and the potential issues that may arise. Just like a skilled musician who knows every note of their instrument, a thorough understanding of these injectors can help in diagnosing problems effectively. From fuel pressure regulation to injector balance rates, each aspect plays a crucial role in the overall performance of your engine.

One key aspect to consider is the common issues that LB7 injectors may face, such as clogging, leaking, or inefficient fuel delivery. Picture them as the heart of your engine, where any disruption can lead to a cascade of problems. By familiarizing yourself with these potential issues, you can proactively address them before they escalate, saving you both time and money in the long run.

Additionally, knowing how to differentiate between normal operation and potential problems is vital. Think of it as being able to distinguish between a well-tuned melody and a discordant noise. By recognizing the subtle signs like changes in engine performance, unusual sounds, or fuel odors, you can take the necessary steps to troubleshoot and resolve any injector-related issues promptly.

Common Symptoms of Injector Problems

When it comes to LB7 injectors, recognizing the common symptoms of potential problems is crucial for early detection and effective troubleshooting. These symptoms serve as warning signs that something may be amiss with your injectors. Let's delve into the key indicators that could signal injector issues:

- Rough idling: Do you notice your vehicle shaking or vibrating excessively when idling? This could be a sign of injector problems affecting the engine's smooth operation.

- Excessive smoke: If you see an abnormal amount of smoke coming from your exhaust, it could indicate fuel not burning efficiently due to injector issues.

- Loss of power: Are you experiencing a noticeable decrease in engine power or acceleration? Faulty injectors can disrupt the fuel delivery, leading to performance issues.

- Fuel leaks: Any visible fuel leaks around the injectors or fuel rail should be investigated promptly as they can indicate seal or injector problems.

By paying attention to these symptoms and addressing them promptly, you can prevent further damage to your LB7 injectors and avoid costly repairs down the road. Early detection is key to maintaining the performance and longevity of your vehicle's fuel system.

Diagnostic Tools and Techniques

When it comes to troubleshooting LB7 injectors, having the right diagnostic tools and techniques is crucial for accurate identification of issues. These tools not only help in pinpointing the problem but also aid in effective troubleshooting and resolution. Let's delve into some essential diagnostic tools and techniques that can assist in diagnosing LB7 injector problems:

- Scan Tools: Utilizing scan tools can provide valuable insights into the engine's performance by reading error codes and data parameters. This information can help in identifying specific issues related to LB7 injectors.

- Fuel Pressure Gauges: Monitoring fuel pressure is vital in diagnosing injector problems. Low fuel pressure can indicate issues such as clogged injectors or fuel delivery problems, helping in narrowing down the root cause.

- Injector Balance Rates: Checking injector balance rates can reveal inconsistencies in fuel delivery among individual injectors. Variations in balance rates can point towards failing or malfunctioning injectors that require attention.

By utilizing these diagnostic tools and techniques, mechanics and vehicle owners can effectively diagnose LB7 injector issues and take the necessary steps to address them promptly. Prompt input and application of these tools to the entire list of symptoms can lead to a comprehensive understanding of the problem, enabling a targeted and efficient resolution process.

Repair and Replacement Guidelines

When it comes to repairing and replacing LB7 injectors, following specific guidelines is crucial for ensuring optimal performance and longevity of your vehicle. Promptly addressing any issues and adhering to recommended procedures can prevent further damage and costly repairs. Here are some essential repair and replacement guidelines to consider:

- Diagnostic Testing: Before proceeding with any repair or replacement, conduct thorough diagnostic testing using scan tools and fuel pressure gauges to accurately identify the problem with LB7 injectors.

- Cleaning Procedures: In some cases, cleaning the injectors may resolve minor issues. Follow proper cleaning procedures using specialized cleaning solutions and equipment to improve injector performance.

- Rebuilding Process: If cleaning does not resolve the problem, consider rebuilding the injectors. This process involves disassembling, inspecting, and replacing worn-out components to restore optimal functionality.

- Replacement Parts: When replacement is necessary, ensure to use high-quality, compatible replacement parts to maintain the efficiency and reliability of LB7 injectors.

- Professional Assistance: For complex repairs or replacements, seeking assistance from experienced technicians or mechanics familiar with LB7 injectors is advisable to ensure proper installation and functionality.

By following these repair and replacement guidelines diligently, you can effectively address LB7 injector issues and enhance the overall performance of your vehicle. Remember, preventive maintenance and timely repairs are key to prolonging the lifespan of LB7 injectors and avoiding unexpected breakdowns.

Preventive Maintenance Practices

Preventive maintenance practices are essential for ensuring the longevity and optimal performance of LB7 injectors. By implementing proactive measures, you can prevent potential issues and costly repairs down the line. Let's delve into some key practices to keep your injectors in top condition.

- Use High-Quality Fuel: The fuel quality directly impacts the performance of LB7 injectors. Opt for reputable fuel stations and avoid low-quality or contaminated fuel that can clog or damage the injectors.

- Change Filters Regularly: Regularly changing fuel filters is crucial for maintaining clean fuel delivery to the injectors. Clogged filters can strain the injectors and lead to performance issues.

- Monitor Injector Performance: Keep an eye on the performance of your LB7 injectors by observing signs of rough idling, smoke emission, or decreased power. Early detection of issues can prevent further damage.

Additionally, it's important to follow manufacturer recommendations for maintenance intervals and procedures. Regularly scheduled maintenance checks can help identify potential problems before they escalate, saving you time and money in the long run. Remember, prevention is always better than cure when it comes to maintaining the health of your LB7 injectors.

Frequently Asked Questions

-

What are the common symptoms of LB7 injector problems?

Common symptoms include rough idling, excessive smoke, loss of power, and fuel leaks. Recognizing these signs early can help prevent further damage.

-

How can diagnostic tools help in troubleshooting LB7 injectors?

Diagnostic tools like scan tools, fuel pressure gauges, and injector balance rates can pinpoint the exact problem with LB7 injectors, ensuring accurate diagnosis and effective troubleshooting.

-

What are some preventive maintenance practices for LB7 injectors?

Implementing regular maintenance such as using high-quality fuel, changing filters on time, and monitoring injector performance can prevent potential issues, ensuring longevity and efficiency of your vehicle.